A Comprehensive Guide on How to Transport Green Hydrogen

The global energy transition has crowned green hydrogen as a cornerstone of our decarbonization strategy. Produced using renewable energy, it’s a versatile, zero-emission fuel. But while we have solved many production challenges, a critical bottleneck remains: delivery.

Getting green hydrogen from a large-scale production hub to an industrial facility, a power plant, or a fueling station is a complex logistical puzzle. The best transport method isn't universal; it depends on scale, distance, cost, and the form of hydrogen needed at the destination.

This guide provides a comprehensive look at the methods, challenges, and trade-offs involved in green hydrogen transport, moving beyond a high-level overview to give you a granular understanding of modern hydrogen logistics.

The Core Challenge: Hydrogen's Density Puzzle

To understand the complexity of hydrogen transport, we must first appreciate its unique physics. Hydrogen has the highest energy content by weight of any fuel, its gravimetric energy density is unmatched. However, in its natural gaseous state, it has an extremely low energy content by volume, a very poor volumetric energy density.

This paradox is the central problem all hydrogen transport systems must solve. To visualize it, 1 kilogram of hydrogen gas (enough to power a fuel cell car for about 100 km) would take up a massive 11 cubic meters of space at normal pressure. Transporting it in this state is completely impractical.

Therefore, to move hydrogen efficiently, its density must be dramatically increased. This is done using three primary strategies:

1. High-Pressure Compression: Squeezing the gas into robust containers.

2. Cryogenic Liquefaction: Chilling the gas to an extremely low temperature until it becomes a liquid.

3.Chemical Conversion: Bonding the hydrogen to another substance to create a dense, stable liquid carrier.

Each of these methods comes with a significant energy penalty. The processes of compressing, cooling, or converting hydrogen consume a portion of the very energy it carries. The challenge, therefore, is to choose a transport method that minimizes this energy loss for a given application.

Primary Methods for Green Hydrogen Transport

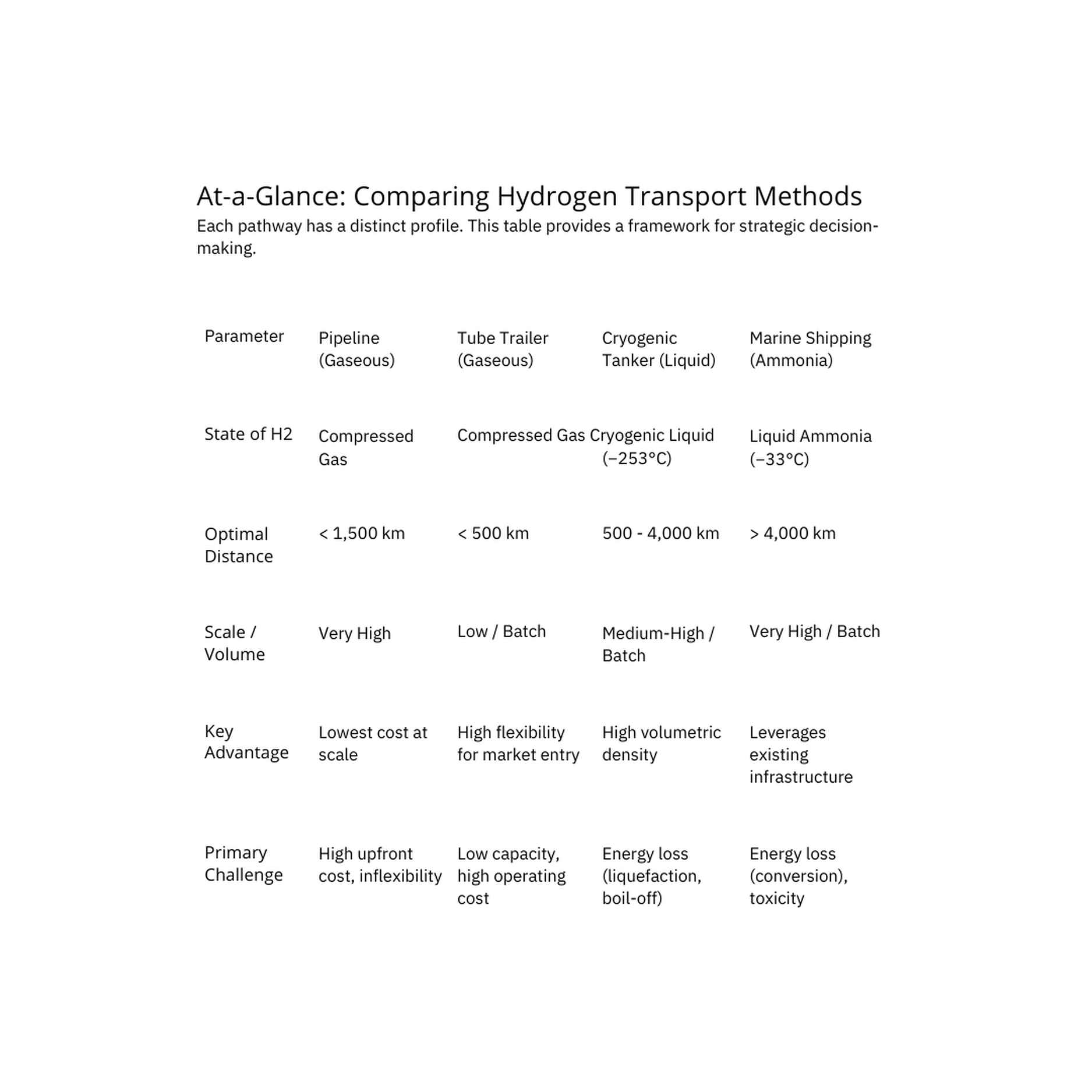

The strategy chosen to densify hydrogen dictates the entire logistical chain. The industry has developed distinct pathways built around moving hydrogen in its gaseous, liquid, or chemically-bound state.

Moving hydrogen as a compressed gas is the most established method, using pipelines for large volumes and tube trailers for smaller, more flexible deliveries.

For moving very large volumes of hydrogen continuously over land, pipelines are the most cost-effective and efficient method. They are the ideal solution for connecting large production hubs directly to major industrial users like steel plants or refineries. Once built, pipelines are the cheapest transport option for distances up to about 1,500 km.

Developers can either build new, dedicated hydrogen pipelines or attempt to repurpose existing natural gas infrastructure. Repurposing is attractive but technically challenging due to hydrogen embrittlement, a phenomenon where tiny hydrogen atoms can weaken steel, making it prone to cracking. This often means repurposed pipelines must be operated at lower pressures. New pipelines built with hydrogen-compatible materials offer a more robust long-term solution.

For smaller volumes or emerging markets, tube trailers are the most practical solution. These are semi-trailers fitted with high-pressure cylinders, acting as a "virtual pipeline" for batch deliveries to fueling stations or industrial sites.Modern trailers use advanced, lightweight composite tanks that can hold hydrogen at pressures up to 700 bar (10,000 psi). However, their main limitation is a low payload, even a state-of-the-art trailer carries only about 1,100 kg of hydrogen. This makes them less economical for long distances.

These two methods create a clear strategic path. A new hydrogen market often begins with flexible tube trailers. As demand grows and becomes concentrated, the significant capital investment in a pipeline becomes economically viable.

To dramatically increase transport capacity, hydrogen can be converted into a liquid. This process requires cooling the gas to a cryogenic -253°C (-423°F), a temperature just above absolute zero. This is highly energy-intensive, consuming up to 30% of the hydrogen's energy content before it even begins its journey.

A single cryogenic tanker truck can carry up to 4,000 kg of liquid hydrogen (LH2), roughly four times the payload of a gaseous tube trailer. These vehicles are essentially giant thermoses on wheels, known as "dewars," with multi-layer vacuum insulation.

A critical challenge is "boil-off." Despite advanced insulation, some heat inevitably enters the tank, causing a small amount of liquid hydrogen to vaporize. This gas must be vented for safety, resulting in a continuous loss of product during transport.

For intercontinental transport, marine shipping of liquid hydrogen is the primary method being developed. This will enable a global market, allowing production in regions with abundant renewables (like Australia or the Middle East) for shipment to demand centers (like Europe or Japan). This requires specialized LH2 carrier ships, technologically similar to today's LNG carriers. While technologically proven, the high costs and energy losses remain significant hurdles.

A promising alternative involves converting hydrogen into a more stable, easier-to-handle liquid chemical. The hydrogen is then released at the destination through a reconversion process.

Green ammonia is created by combining green hydrogen with nitrogen from the air. The resulting liquid ammonia can be used directly as a fuel or "cracked" back into hydrogen.

Ammonia's foremost advantage is that it can leverage the massive, mature global infrastructure already in place for its production and shipping (thanks to its use as fertilizer). It liquefies at a manageable -33°C, making it far less energy-intensive to transport than LH2. However, ammonia is toxic and requires strict handling, and the technology for cracking it back into high-purity hydrogen is still maturing.

LOHC technology involves chemically bonding hydrogen to a stable, non-toxic organic liquid, similar to diesel oil. This "hydrogen-rich" oil is then safely transported using existing infrastructure for liquid fuels, pipelines, trucks, and ships, with little modification required. At the destination, the hydrogen is released, and the "lean" carrier liquid can be returned for re-use. The main drawback is the energy required for the dehydrogenation step to release the hydrogen.

Conclusion: A Multi-Modal Future for Green Hydrogen Transport

There is no single "best" way to transport green hydrogen. The future of hydrogen logistics will be a sophisticated, multi-modal, and integrated network where different pathways work in concert.

Here’s a comparative scenario to put things into perspective: an offshore wind farm produces green hydrogen, converts it to ammonia, and loads it onto ships for export. At the destination port, some ammonia is used directly as marine fuel. The rest is cracked back into hydrogen, which enters a regional pipeline to supply nearby steel mills. From there, the hydrogen is compressed into tube trailers for delivery to smaller industrial users or liquefied for a network of heavy-duty truck refueling stations.

This integrated vision is the path forward. Overcoming hydrogen's logistical challenges requires sustained innovation, strategic investment, and an unwavering commitment to safety. Successfully navigating these hurdles is the key to unlocking the full potential of a truly global, clean energy economy.